If you use compressed air, then there may be times when you noticed that you have droplets of water within the air distribution system. Having accumulated moisture is not a good sign. Moisture is the number one cause of corrosion.

Corrosion leads to damage of the machine parts or complete failure of the machine. In order to prolong your machine’s lifespan, you need something that is going to get rid of the moisture from the compressed air, and an air dryer does just that.

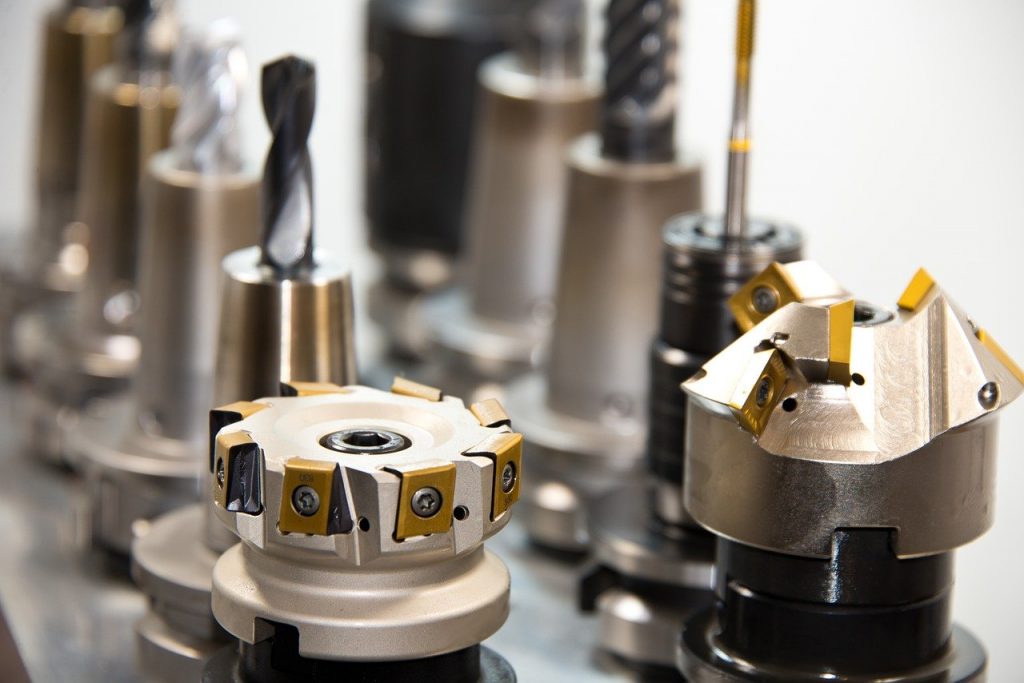

To protect your tools, equipment and piping, it is a good idea to use a compressed air dryer so it can dry the air.

The refrigerated air compressors are the most common that are used. Simple in design, cheap to purchase and run and need very little maintenance.

A refrigerated air dryer is the most standard choice if you are looking for a dryer and don’t require any special needs like ultra-low dewpoints. The best thing is if you buy a good quality one and get it installed properly then it is just set and forget.

How do they work?

Just like the name implies, the refrigerated air dryers work by cooling down the air as a normal refrigerator would. The warm wet air enters the refrigerated air dryers where it is cooled down to around 3 degrees Celsius. The water vapours that are in the air are condensed into water.

Look at it the same way as the windows in your home when it is a cold day. The liquid water is taken from the compressed air dryer by a water trap. The cold air is re-heated to around room temperature. Much of the water has then been condensed into the water, so the air becomes more dryer as a result.

The cooling is done the same way that your fridge and freezer are cooled. In a different circuit, the liquid refrigerant is evaporated within the evaporator, which cools down the compressed air. The air is cooled down, while the refrigerant gets hotter. The refrigerant gets compressed by a small compressor and then cooled down again in the condenser.

The different types of refrigerated compressed air dryers

There are two types of air dryers. You have the cycling and non-cycling. The advantage of the cycling dryer is that it will decrease or increase the cooling capacity according to the air use. Reducing the energy that is being used and will save you money in the long run. The non-cycling is the common type out of the two as it is low maintenance and very reliable.

Are there any benefits to a refrigerated dryer?

- Energy saving

- Low initial cost

- High reliability

- Easy to maintain

- Will extend the life of your compressor

A refrigerated air dryer is an essential piece of equipment that is used to ensure the optimum productivity of your compressor.

The air dryers have an essential role in keeping your equipment safe from the effects of moisture. The overall performance and efficiency of the manufacturing process can be significantly improved just by installing a refrigerated air dryer.

These machines seem to offer plenty of benefits which is why most commercial buildings are using them for all types of business industries.